Cost of Sales Inventory Boosts a Restaurant’s Profitability

How does a comprehensive inventory positively impact your cost of sales and overall your bottom line?

When consulting with operators about their cost of sales, one of the first questions I ask is how often they are doing inventory. The way they answer that question tells me everything I need to know about their entire operation. It’s no surprise that many had no system in place at all, and most that do, have the wrong idea about what a proper inventory is and how it can dramatically change their profitability.

According to many sources including the National Restaurant Association, operators who have an inventory system and controls in place have on average an 8-9% reduction in food cost. In this article I’ll discuss understanding the importance of this simple yet effective strategy. I’m also going to go over some of the basic principles I use in implementing an inventory system and how to use it correctly.

1.The purpose of inventory

The purpose of inventory simply is to get an accurate picture of what your Cost of Goods or Cost of Sales are for any particular area. However by simply implementing a system several byproducts begin to naturally occur and have a long lasting effect.

- Cost of sales reduction – knowing where opportunities are

- Reduce Theft – awareness of tracking decreases temptation

- Product Awareness – knowing what’s on hand and usage rate

- Reduce waste due to spoilage- helps prevent over ordering

2. The different inventory types

I’ve encountered many operators who used at-a-glance, on-hand counts when referring to inventory. This leads to inconsistent results and food cost percentages that range widely causing frustration for operators struggling to understand how to control that number.

The key concept here is to understand the difference between conducting an inventory to balance cost of sales and on-hand counts to order food stock.

Comprehensive Cost of Sales Inventory

- Everything gets counted

- Provides the true value of your entire stock

- Consistent accuracy of cost of sales numbers

- Shows you real areas of opportunity

- A system that’s measurable

Truck Order Inventory

- In most instances doesn’t take into account prepped products

- Gives inconsistent cost of sales information

- Broad product variances due to incomplete count

- True product value is unknown

- Simply not getting a complete picture

3. Putting a system in place

This is by far the most vital step you can take toward controlling your cost of sales. Most operators dread the word inventory because they fear it’s a labor intensive, tedious task that only corporate bean counters (no pun intended) institute.

The truth is, professional restaurateurs know this is an essential part of their restaurant’s success. We also know that a simple and effective system will streamline the burdensome tasks.

Having the right information is powerful. By knowing what your costs are and having them categorized, you are able to identify and have clear information about where to focus your management efforts.

4. Your POS System is your Best Friend

There are so many POS Systems available on the market now that are full of capabilities specifically designed for restaurants.

A POS System automates so many functions and allows you to tailor various reports or tools to your specific needs. Let’s look at a few:

Specifically related to Cost of Sales and Inventory:

- DSR – Daily Sales Report

- Master Product List

- Count Sheets

- Inventory Price Updates

- Price Presets and Batch Recipes

- Product Mix Report

5. A good starting point

Have Neatly Organized Storage Areas

Organization is everything. There’s a place for everything and everything has its place. Following this simple idea will make the process of inventory much easier and faster.

- Label your storage areas, shelving and racks

- Engage your staff to the expectation of a neatly organized area

- Have diagrams of racks and spaces where they’re clearly visible

- Organized storage areas are easier and to count, making for a fast, efficient process

6. Inventory Count Sheets

Shelf to Sheet Inventory

When it comes to count sheets, you may have several. Categorize each storage area into its own sheet, and organize it so that it matches the storage area.

When you count, start from the top and work your way to the bottom of each rack, going along each shelf. Count by the rack, not the sheet. Counting with this method ensures you won’t miss anything.

DRY STORAGE | ||||||

|---|---|---|---|---|---|---|

| Rack 1 | Count By | Count 1 | Count 2 | Count 3 | Total | |

Ketchup | Case | |||||

Gravy Mix | Each | |||||

Coffee | Case | |||||

Coffee | Each | |||||

Tea | Case | |||||

Tea | Each | |||||

Rice | Bag | |||||

Rice | Lb. | |||||

Rack 2 | Count By | Count 1 | Count 2 | Count 3 | Total | |

House Sauce Red | Each | |||||

House Sauce Green | Each | |||||

Salad Oil | Gallon | |||||

Mustard | Gallon | |||||

Steak Sauce | Each | |||||

Mayo | Gallon | |||||

Batter Mix | Lb. | |||||

Batter Mix | Bag | |||||

Sugar | Lb. | |||||

This way the count sheet goes with each rack. If you have new items you can add them by hand and put them into your sheet later. The different Count numbers don’t represent individual or separate counts, but a cumulative count.

For Instance:

Rack 2 | Count By | Count 1 | Count 2 | Count 3 | Total |

|---|---|---|---|---|---|

House Sauce Red | Each | 37 | 9 | 46 |

You counted Rack 2 and there were 37 bottles in an opened case of your house red table sauce. While counting Rack 5, you found 9 bottles out of place. For speed and efficiency, just put 9 in the count 2 box and let the system do the math.

You want at least a separate sheet for each storage area.

For Example:

- Freezer

- Walk-In

- Dry Storage

- Line

Create separate sections in each sheet as needed.

Take your line for instance:

- Sandwich Cooler

- Server Reach-In

- Expo Table

- Fry Station

- Saute Reach-In

- Etc.

If this seems like a lot to take in, then start by taking one area at a time and make a list as if you were going to count it according to this method. Start small, like with a small reach in or cooler. You now have a blueprint for your first sheet. Better yet, delegate some of it to some key kitchen staff and get them on board.

7. Value of prepped items

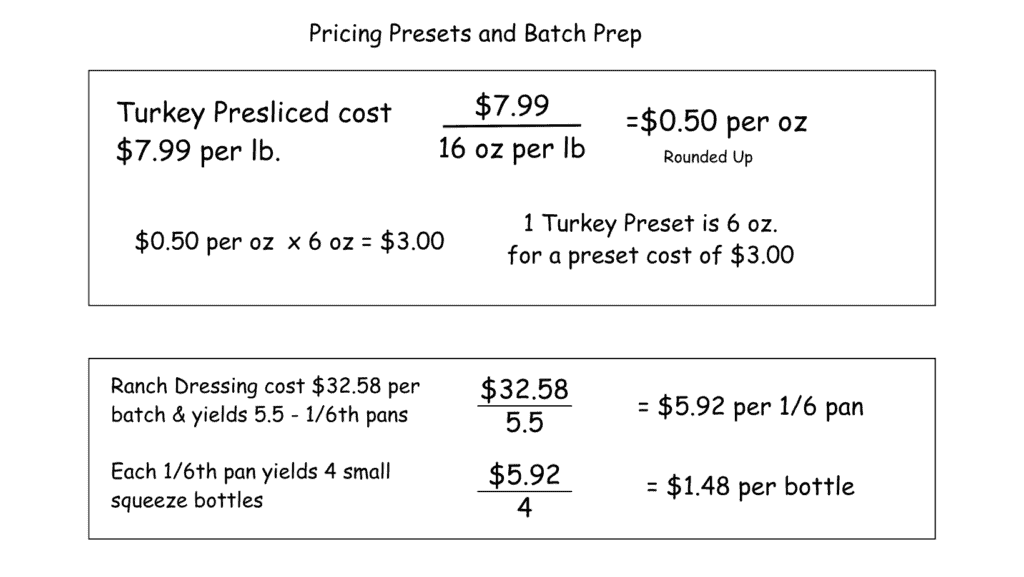

To truly be efficient in our counts we need to have batch recipes and preset prices calculated and costed out.

If you’ve costed out your menu then you should have this information readily available. As well as menu costing and your pricing strategy should be done periodically.

Most POS systems have the capability to automate this task as well, however the process is simple:

Using those numbers, our inventory count sheet would look like this:

Sandwich Cooler | Count By | Count 1 | Count 2 | Count 3 | Total | Cost | Total Value |

|---|---|---|---|---|---|---|---|

Turkey Sets | Each | 14 | 14 | $3.00 | $49.00 | ||

Ranch Dressing | 1/6 Pan | 2.3 | 2.3 | $5.92 | $13.62 | ||

Ranch Dressing | Bottle | 3.5 | 3.5 | $1.48 | $5.64 | ||

Sliced Tomatoes | lb | 2 | 2 | $1.38 | $2.76 | ||

Sliced Tomatoes | 1/6 pan | 1 | 1 | $4.93 | $4.93 | ||

0 | $ – | ||||||

Total Value of Sandwich Cooler | $75.94 | ||||||

Having all of your batch recipes and presets priced correctly and storage methods consistent streamlines the counting process.

8. How to Count

When getting ready to count inventory it’s generally a good practice to develop a routine that will make you faster and more efficient over time.

- Use a cart and supply it with the following:

- Pound Scale

- Ounce Scale

- A few empty pans for tare weights

- Empty box for trash

- Use physical sheets

- I like to use actual paper and pencil when counting

- Take notes if needed

- Do scratch math on the fly

- Reduced wear and damage on handhelds or tablets

- Enter your counts into the system in your back office

- Employ a partner

- Having a second person can speed up the process

- One person counts while the other writes

- Two sets of eyes helps ensure accuracy

- Creates training and coaching opportunities for key employees

You will find that eventually this will become second nature. You’ll be able to count some areas while running your shift.

You’ve made cuts to the floor, business is winding down and pre-close has started. You can count a storage area in 15-20 minutes and even lock it up if necessary.

By the time you lock the doors, the only thing left to count will be the main use areas such as the line or server stations etc.

9.When To Count

Your goal should be to do a full inventory count at least once a month. Always count on the last day of the period. Whatever day you close out your monthly financials is when you need the inventory numbers. If you’re not doing monthly financials, well that’s a whole other article.

- A bi-monthly or even a weekly inventory is suggested.

- If you know where to focus your efforts you can impact those areas and take steps toward correcting them.

- In a small operation with no assistant management staff, at least try to focus on a once a month count to get started in the right direction.

- When getting started or putting an initial system in place, a weekly inventory for at least 4 to 6 weeks will provide you with a strong baseline of your true cost of sales.

Once you have an established system in place I generally opt for a bi-monthly system. By doing a count with this frequency, you may spot areas that need attention or where costs may be starting to creep up.

Let’s Close Out

While no system is perfect, or works for everybody, there is tangible value in each of the steps I’ve discussed. Only you know what’s right for your restaurant, your guests, your staff, and ultimately your bottom line.

If you’ve got a great inventory system already, then Great! If not then I know some of these tips will help you understand how to begin to create one. Cost of sales, especially food cost isn’t fixed overnight in most instances, but you can take steps daily to improve and put systems in place that make managing it so much easier. Do something today that makes your next shift, your best shift!